Mass timber construction is on the rise as owners, architects and contractors champion low embodied carbon building materials. In our continued video series, we look at Maine’s first fully timber structure at Bowdoin College’s John and Lile Gibbons Center for Arctic Studies and Barry Mills Hall. The all-electric building will support low carbon operations through a fossil-fuel free approach.

How does Consigli—which has planned and built more than fifteen projects incorporating timber solutions—coordinate and collaborate with our project partners to plan and deliver high-quality timber structures? With extensive experience analyzing, procuring and installing mass timber, Consigli’s interdisciplinary approach supports our clients—like Bowdoin—in making cost-effective, schedule-driven decisions when planning a mass timber project.

Initial Design

Rigorous pre-construction planning is a must when it comes to mitigating potential cost, schedule and quality impacts associated with a mass timber structure.

Rigorous pre-construction planning is a must when it comes to mitigating potential cost, schedule and quality impacts associated with a mass timber structure.

- Early Detections of Issues: The smallest details matter when it comes to achieving the desired look and function for such a specialized finish product. Incorporating design intent into early models helps guide crucial design considerations to be incorporated into fabrication documents and allow for timely timber release.

- Structural Reviews: Structural drawing reviews help analyze column spacing, spans of timber elements, choices of direction of primary girders and varying strategies for mechanical ductwork and plumbing routing. The review process can potentially result in cost saving through elements including reducing beam sizes and floor plate thickness.

- Cost Competitiveness: In today’s ever changing and challenging materials market, mass timber has remained relatively steady in pricing. This certainty allows mass timber to be priced early with greater assurance of costs as the project progress. Depending on the application, mass timber pricing can be very cost competitive when compared to steel and concrete and has additional cost benefits in terms of fit-out costs. Mass timber can also remain exposed, reducing the costs of expensive interior finishes on a project.

Selection & Sourcing

Timber species selection can affect the mass timber manufacturer. The right decision-making can support early internal estimates and analyze specific species for the best fit.

Timber species selection can affect the mass timber manufacturer. The right decision-making can support early internal estimates and analyze specific species for the best fit.

- Wood Species & Material Finish: Material selection has a significant impact on the choice of timber manufacturers. From aesthetic to strength of structural design to lengths of members, Consigli can help evaluate timber species and offer options that satisfy aesthetic and structural need.

- Deep Knowledge of Supplier/Manufacturer Market: A strong list of suppliers, both domestic and foreign, ensures competitive pricing for initial bidding during earlier phases of design. As the mass timber is fully designed and released for fabrication, a well-established market knowledge is crucial in bidding installation.

Coordination & Release

Coordination model completion ahead of Construction Documents is critical to final fabrication shop drawings for mass timber. With timber lead times ranging from 16 to 24 weeks from final drawing approvals, time is of the essence.

Coordination model completion ahead of Construction Documents is critical to final fabrication shop drawings for mass timber. With timber lead times ranging from 16 to 24 weeks from final drawing approvals, time is of the essence.

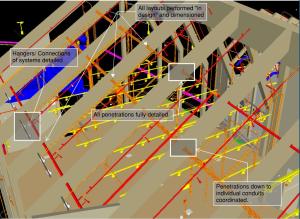

M/E/P coordination for a mass timber structure.

- M/E/P/FP Coordination: Mass timber penetrations for M/E/P/FP systems must be carefully planned and integrated into fabrication documents. Coordination models for these penetrations allow all pathways to be designed and manufactured in shop in lieu of in field; this is crucial as field cutting is prohibited for this level of finished product.

- Design-Assist Engagement: Engaging design-assist partners for M/E/P/FP systems and mass timber allows the project team to coordinate within the working design model. Creation of CD-level documents through design-assist, even as the rest of the design is in early stages, supports completion of building systems and architectural features for a release of timber well ahead of CDs, mitigating the challenge of timber long lead times.

Delivery & Installation

Careful attention must be paid to the handling, installation and protection of mass timber to maintain the material’s integrity. Hands-on installer experience is imperative when planning a successful mass timber project.

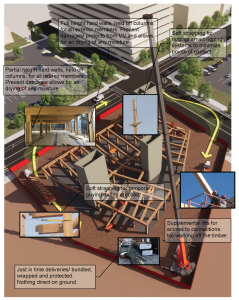

Mass timber logistics & installation considerations.

- Logistical Planning Handling & Installation: Development of the right logistics plans for efficient installation—accounting for any potential double handling and required special care—is paramount to creating schedule certainty through installation. The right project partners develop proper delivery, loading and sequencing unique to each site.

- Protecting your Investment through Insurance & Temporary Protections: Consigli’s in-house Job Site Insights platform allows our clients to protect their investment through floor-by-floor detection of potentially damaging elements to the timber structure, including water, fire or any other elements that may stain or mar the finished product. Additionally, temporary protection is often required and includes the use of hard walls held off the timber columns for UV and moisture protection, floor plate protection from UV, moisture and foot traffic, maintenance of humidity and temperature post close-in. The most effective timber structure protection is speedy building enclosure to reduce environmental impact on the timber itself. Once enclosed and final systems are brought online, maintaining proper humidity levels is critical to keeping the timber looking and functioning at its best.

- Self-perform Capabilities: Consigli self-performs mass timber installation and protection, giving us added control over schedule, quality and continuity of installation because we are that much closer to the product. Our 650 in-house craftspeople share our standards for quality and are a strong additional resource to call upon to get work done on time.