Dartmouth Hitchcock Medical Center (DHMC) is the only Level 1 trauma hospital in New Hampshire, providing primary and specialty care to patients throughout New Hampshire and Vermont. Despite DHMC’s technical staff having the ability to support the area’s most complex cases, their facilities could not meet patient base demand and often exceeded capacity, forcing DHMC to turn away hundreds of patients per month.

In 2018, the DHMC board approved the construction of a new, six-story 240,000 square foot Inpatient Tower, expanding services and capacity by adding 64 state-of-the-art inpatient beds and shell space for future flexible expansion.

The facility was designed with an interdisciplinary and “future-proof” approach. Patient rooms provide flexibility to serve as med/surg, step-down, or even critical care options, depending on need. Each room is private and offers space for visitors to be with their loved ones during their stay. And, technology is at the forefront, with integrated patient dashboards, MyChart Bedside, and telemetry units, allowing patients to interact with their provider teams at their fingertips.

The Challenge: Location-based Labor Shortages

The Upper Valley is a collection of small, quintessential New England towns along the Vermont/New Hampshire border. The area is large, but the population is low, and DHMC is the only hospital within many miles for these residents.

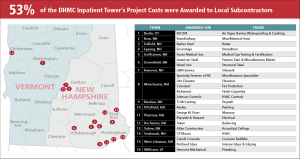

DHMC’s priorities and obligation to Upper Valley residents extended beyond the care they were providing. It was important to the hospital to put the Upper Valley to work through this significant construction project, and to the extent it was possible, keep the labor and vendor base local.

Consigli’s knowledge of the New Hampshire subcontractor market and capabilities informed a thoughtful strategy to do just that, ultimately keeping over 50% of the project spend with local firms.

The Solution: Thoughtful Procurement & Intentional

Pre-fabrication

Keeping the Work Local: The Consigli team took a holistic view of the planning and buyout for this project: identify which scope areas could be supported by local subcontractors and vendors, and then determine where there were opportunities to introduce creative solutions—like pre-fabrication and material pre-purchasing—that would infuse greater efficiencies into the project.

To start, the team mapped out all local subcontractors with the size, capacity, and experience to take on a project of this scale and complexity. The subcontractors were invited to an open house event where they could learn more about the project, meet the Consigli team, and get a sense of the expectations and timing for bidding.

“Our plan was to use local labor whenever we could, and when we maxed out that avenue, we explored creative solutions that could enhance the overall delivery of the project,” said Ricky Gala, Senior Project Manager.

Pre-purchasing Equipment for Schedule Certainty: During Design Development in February 2020, Consigli and designer HDR proactively mapped out decision deadlines for material purchasing, advising on workarounds wherever possible. This is a risk management strategy that Consigli employs on all projects, but it proved critically important and timely at DHMC as COVID hit.

As the world was facing unprecedented uncertainty in early 2020, Consigli’s DHMC team was preparing to break ground on the long-awaited (and much needed) Inpatient Tower. Instead, their focus shifted toward forecasting looming material shortages, supply chain issues, border shutdowns, and astronomical price increases.

“From the beginning of the project, well before COVID was ever heard of, we planned this project to be as schedule and labor-resilient as possible…and then the pandemic really stress-tested that approach,” said Consigli Director of Pre-fabrication Bill Seery.

Consigli secured steel prices before costs skyrocketed and bought from a New Hampshire-based steel mill to avoid potential U.S./Canada border issues. All M/E/P equipment was pre-purchased, locking in early pricing to avoid escalation and circumnavigating long equipment lead times, getting materials to New Hampshire well before they were needed.

It also provided other benefits, like allowing the M/E/P equipment to be designed into the building, and all structural slab requirements and electrical could be fully coordinated in advance, eliminating clashes and field re-work.

This proactive approach extended to commodity items, too. Piping, insulation, roofing, and drywall were prioritized; subcontractor onboarding was expedited, submittals and reviews were fast-tracked, and materials were ordered. Warehouse spaces in Nashua, Enfield, and Seabrook, NH as well as Windsor, VT were used to store the materials until they were needed much later in the project. This fast-tracked procurement approach proved critical as lead times increased nearly 500% on many commodity items during the pandemic.

By April 2020, the Consigli team had locked in its subcontractor and vendor base, pre-purchased materials, and had a solid plan going into the Inpatient Tower groundbreaking, set for July 2020.

“If we weren’t proactive about the way we approached procurement and pre-fabrication on this project, we would’ve been caught on our heels when COVID hit,” said Gala. “We weren’t reacting to a problem and trying to change course. We planned the project in the most efficient way possible, and when the pandemic hit, we were in the best possible situation to take it head-on.”

See how Consigli’s equipment and commodity pre-purchase strategy safeguarded the project when COVID hit, and lead times skyrocketed.

Pre-fabrication for Enhanced Delivery: “The way we go about pre-fab…it’s very systematic. We think from the site all the way through the M/E/Ps and finishes,” explains Brian Hamilton, Consigli’s Vice President of Healthcare & Life Sciences. “When you approach pre-fab as removing labor from a jobsite, it opens up people’s minds; they aren’t just thinking about the standard pre-fabrication elements.”

Every aspect of the DHMC pre-fabrication approach was deliberate. The selected scopes needed to add value to the finished project or the way it was delivered. From the smallest solutions like pre-installing hardware on doors, to large-scale improvements like a structural shift to bolted connections, or driving the exterior design for pre-fabrication, the decisions had to improve quality, increase speed of delivery, save money, or remove on-site labor to mitigate campus disturbances and make the jobsite safer.

“Consigli went into this project knowing the value and advantages that pre-fabrication would bring. When HDR had roughed out a conceptual massing diagram, the entire DHMC project team started collectively digging into the elements of the job that we wanted to pre-fab,” continues Hamilton. “It was really important that we started this out of the gate, because in some cases, it changed the way we approached the building.”

By pre-fabricating systems that directly impacted care delivery and the patient experience, items like headwalls, med gas racks, and wet walls, Consigli and the client team were able to inspect early and often, ensuring the assemblies met DHMC’s exact specifications and standards of care. It also helped keep the schedule in-line by reducing the risk of defects and non-compliance that would need to be repaired or replaced during punchlist.

“By going into the Inpatient Tower project aware of these potential delay ‘traps,’ pre-planning, pre-procuring, and pre-fabricating were all applied to mitigate and diminish these risks,” said Seery. “Our goal on every project is to eliminate risk through intensive pre-planning, and the results at DHMC showcase the fruits of that effort.”

Check out the video below to see what was pre-fabricated and the value it added to the DHMC Patient Tower project.

Turning Over the Tower

Three years after COVID called into question the feasibility of DHMC’s long-awaited project, the Inpatient Tower is opening its doors to the Upper Valley community, providing close-to-home care and a patient experience that rivals its neighbors in Boston and Portland.

Dartmouth Hitchcock Medical Center’s state-of-the-art tower has increased the hospital’s ICU capacity by 228%, with an additional two floors of shell space for a flexible expansion and space for 64 beds which could increase capacity by 356% when fit-out. The main entrance to the hospital is welcoming, with a comfortable lobby, beautiful chapel, easy-to-access amenities and services like food and beverage stations, a lactation room, and an expanded discharge lounge for DHMC patients.

The once too-small hospital is now a landmark for primary and specialty care in the Upper Valley.