Consigli is leading the way in sustainable construction by embedding circular economy principles into every project, reducing waste and maximizing reuse. According to the U.S. Environmental Protection Agency, more than 75% of construction and demolition waste could be reused, repurposed or recycled, yet most of it ends up in landfills. The realities of deadlines, budget constraints and limited supply chain infrastructure force the disposal of reusable resources—like lumber, equipment and overstock—complicating the shift toward a circular construction. At Consigli, we’re proving there’s another way. By embedding circularity into our operations, we’re turning construction waste into a resource that supports new work, reduces costs and advances sustainable building with strategies that can be scaled industry-wide.

Consigli’s Circular Construction Model

Consigli’s circular construction strategies are built on three key pillars:

1. Internal infrastructure;

2. Strategic investment in circular materials and equipment; and

3. The right partners.

Internal Infrastructure

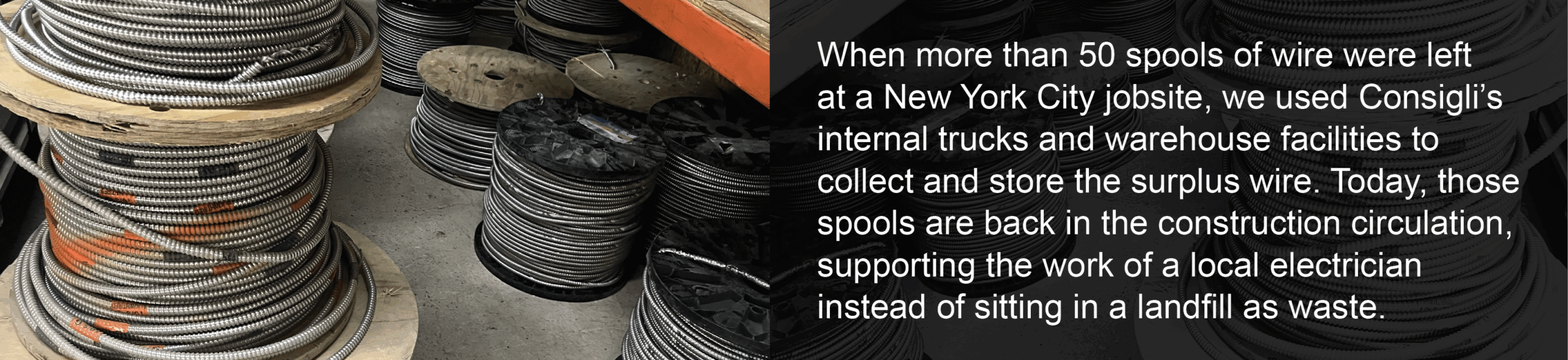

Our fully integrated Supply and Equipment division is backed by Consigli-owned warehouses, trucks, labor and systems that streamline logistics and accelerate procurement. This unique infrastructure enables our team to recover excess materials from jobsites and return them to our warehouses where they’re cataloged, preserved and prioritized for reuse. When another Consigli site requests materials or equipment, our centralized purchasing team’s first step is to evaluate what’s available internally, minimizing new purchases and keeping valuable resources in circulation. By tapping into our existing inventory, we reduce waste, cut costs and improve speed to site—all while advancing our circular construction operations.

Strategic Investment in Circular Materials and Equipment

Selecting products with long lifespans reduces reliance on single-use resources while lowering procurement costs and waste removal fees. Take STARC panels—modular wall systems designed for repeated use—for instance. During the height of the COVID-19 pandemic, Consigli deployed more than 1.5 miles of these walls on emergency healthcare projects, including triage units at local hospitals. With dedicated warehousing and logistics in place to collect, store and redistribute recycled construction materials, those same STARC panels remain in active use across Consigli projects today. This kind of strategic investment in durable, reusable materials and equipment reduces environmental impact and delivers measurable cost savings across projects.

The Right Partners

Engaging the right partners is essential to closing resource loops across the value chain and extending circular strategies beyond a single organization. By working with like-minded organizations, we amplify impact. Through our partnership with Evolve Resource Management (EvolveRM), we transformed our dated hardhats into plastic pellets, which were then used to manufacture pallets. These pallets are now actively used by our Supply and Equipment division. In the Boston market, Consigli also deploys Wasted* portable restrooms—units that use diversion technology to convert human waste into slow-release fertilizer for gardening. Partnerships like these ensure that waste-to-resource solutions are not just internal goals. They’re shared, long-term commitments.

Scaling Circularity Across the Construction Industry

Consigli’s circularity model challenges the notion that sustainable building is a cost center. By implementing systems that streamline material reuse and reduce construction waste, the model directly addresses rising costs, resource scarcity and the growing demand for sustainable practices. Now, Consigli is committed to building a collaborative circular economy in construction where contractors share recycled construction materials across job sites and organizations, transforming surplus into opportunity. This scalable approach sets a new industry standard, proving that waste reduction, resource sharing and sustainable construction can drive both operational efficiency and long-term environmental impact.

Consigli’s circularity model challenges the notion that sustainable building is a cost center. By implementing systems that streamline material reuse and reduce construction waste, the model directly addresses rising costs, resource scarcity and the growing demand for sustainable practices. Now, Consigli is committed to building a collaborative circular economy in construction where contractors share recycled construction materials across job sites and organizations, transforming surplus into opportunity. This scalable approach sets a new industry standard, proving that waste reduction, resource sharing and sustainable construction can drive both operational efficiency and long-term environmental impact.

“Consigli’s circularity model has the potential to reshape construction’s environmental footprint—turning waste into opportunity. We’ve seen firsthand how this approach delivers operational efficiency, financial value and measurable sustainability for our clients and our jobsites.”

Jon Burton, Director of Supply and Equipment